We establish an effective characterization process flow for micro-optics fabrication. Each characterization answer different question based on our designed metrics. This characterization logic is generizable for other printing process from two-photon polymerization.

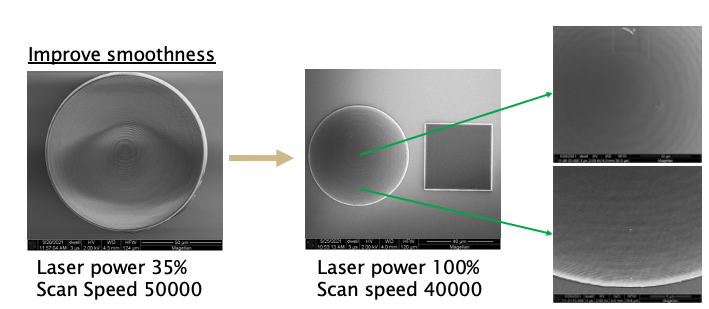

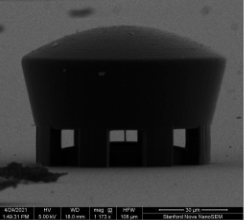

Scanning Electron Micorscopy (SEM)

SEM is intended to evaluate surface property and internal structure of the lens. SEM can provide qualitative information of surface property after printing. For the following images, SEM reveals the staircase effect after printing and help us evaluate smoothness of the structures.

From the 90 degree SEM, we can use this technique to evaluate the internal structures. In this characterization, we found that if the doublet lens were printed at the origin, there is a string showed up in the internal structure.

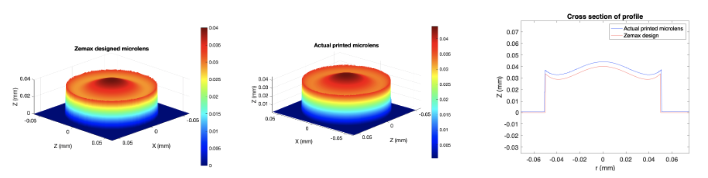

Keyence laser confocal microscope

Keyence laser confocal microscope confocal microscope provides topography and height information and this allows us to match surface profile.

Keyence 3D microscope

Keyence 3D microscope is a direct way to visualize the lens. This microscope can be operated in transmissive or reflective mode and sunstrate can be evaluate under 0 degree or 90 degree.

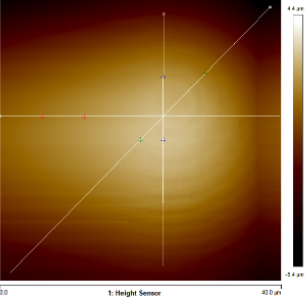

Atomic Force Microscopy (AFM)

AFM is intended to provide microscopic suface smoothness property