In terms of development, the standard processing is 20 minutes SU8 developer followed by 10 minutes IPA. However, in the process of IPA drying, the tension created by the solvent could potentially collapse the delicate structure. To deal with this issue, several development method are implemented and could minimize the structural deformation during drying.

The first way is using HFE7100 for drying. HFE stands for hydrofluroether and consists of complex cleaning solvent that does not occur naturally in the environment. The advantage of HFE solvent is having a very low surface tension and could preserve structural integrity.

The second way is using critical point dryer to remove IPA. It eliminates surface tension associated drying of liquid by avoiding phase transition boundary from liquid to gas.

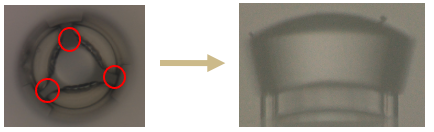

Here we show an example using HFE as a rinse solvent could preserve an overhanging structure for microlens.