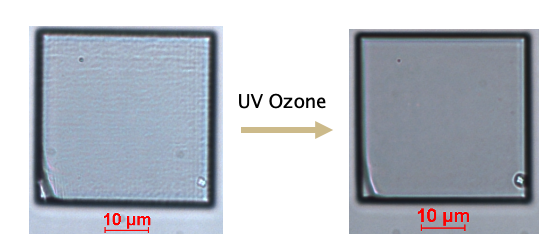

After development of our printed structures, we careful inspect our printed structures and found a intrisic inhomogeneity of exposure exist. This inhomogeneity leads to a grid artifact inside of the structures. Since we speculate this came from the inhomogeneous exposure, we treat the printed structures with UV and in hope to minimize this artifact. The following figure shows our UV-ozone treatment is quite effective and it improve the homogeneity of the printed structures.

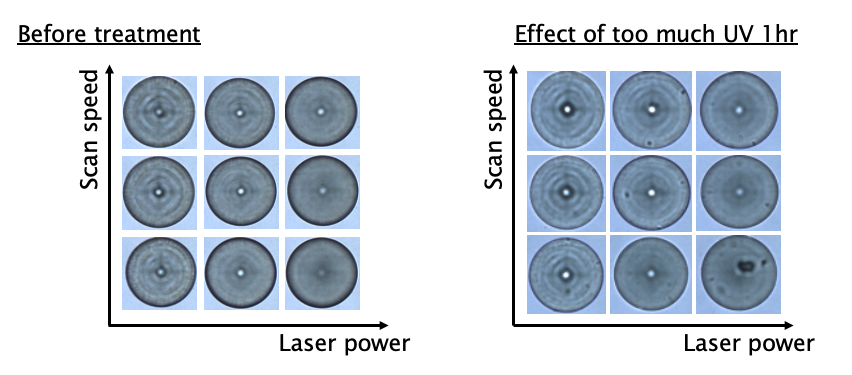

However, since UV-ozone etch the resin when it cleans, we also found that over-treatment damage the structures and need to be very careful. Here is an image shows the lens after UV-ozone treatment for 1hr. Many lens damaged after treatment.

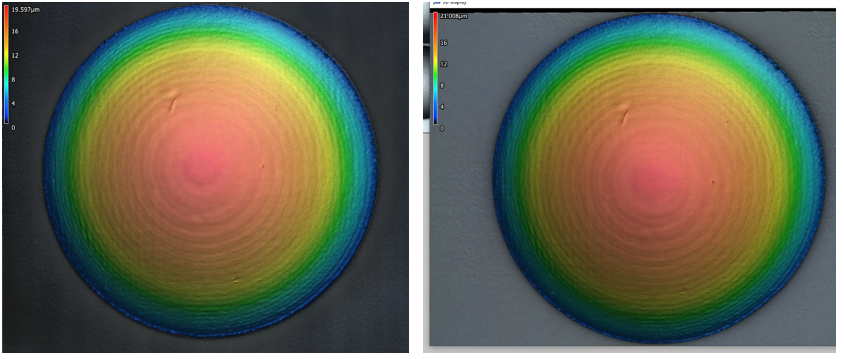

We also tried temperature reflow for smoothening the surface. However, we found that IP-S is a resist which is very difficult to reflow. Even we heat the resist up to 200 degree for 10min, we still see very little change on the surface topography.