In terms of writing, we identify two common problems happened during the writing process. The first thing is the structural stability. If the structural stability is not enough, the structure is easy to collapse after development. We also introduce development strategy in another tab to minimize tension during development. However, simply include more supports in the structure could strongly enhace the structural stability.

The second common issue is bubbling. By preheating the IP-S resin on hotplate under 60 degree for 15 min. We found that this minimize the bubbling and strongly increase the writing repeatability.

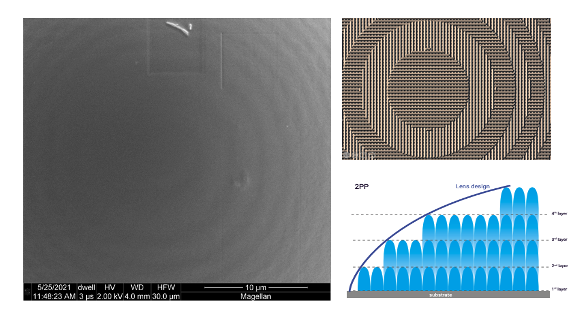

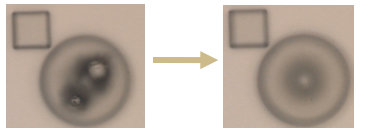

After the writing, we observed some staircase effect on the surface. This staircase effect mainly comes from the slicing and it plays the major role to affect our lens smoothness. To reduce this staircasing effect, one straightforward way is to use the smallest slicing distance (0.1 um). However, this reduction would alse significantly increase the writing time. Another alternative way is to use 0.2 um slicing distance but do a 3min UV-ozone treatment on the lens. We found that’s a more ideal method in the prototyping stage.